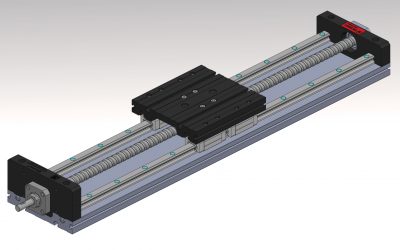

Belt Drive Linear Modules

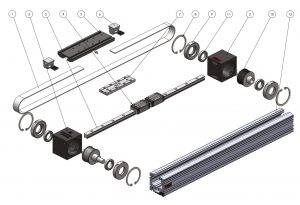

Belt drive linear actuators are an economical solution to high-speed motion for light and medium size loads. They consist of an extruded aluminium body which provides rigidity and a moving carriage running on linear rails. The carriage is connected to a toothed timing belt running the length of the body, driven by a rotary motor at one end.

Belt drive linear actuators are an economical solution to high-speed motion for light and medium size loads. They consist of an extruded aluminium body which provides rigidity and a moving carriage running on linear rails. The carriage is connected to a toothed timing belt running the length of the body, driven by a rotary motor at one end.

Our units are truly modular and can be supplied with your choice of motor technology, or even without a motor for integrating your own. We also provide accessories for mounting the single units into multiple axis combinations for applications such as 3D printers, cartesian robots and laser materials processing systems.

WMCS HEAVY DUTY MODULES

WMCS HEAVY DUTY MODULES

Our largest and most precise model, the WMCS is available with up to 4m stroke and can support dynamic loads up to 28kN with a repeatability of <0.1mm.

-300x200.jpg) H SERIES LINEAR MODULES

H SERIES LINEAR MODULES

80mm profile gives high rigidity and load capacity.

-

Load capacity: 50kg

-

Stroke: up to 4m

-

Self-cleaning linear guides

W SERIES LINEAR MODULES

W SERIES LINEAR MODULES

Our most popular unit – medium precision and very low cost. Ideal for 3D printers and pick & place systems.

Four variants based on 40-60mm profiles offer load capacity from 6kg to 35kg and strokes up to 4m.

T SERIES LINEAR PUSHER

T SERIES LINEAR PUSHER

A belt drive module with an external actuator shaft makes the T series ideal to replace pneumatic cylinders in ejection/divert applications and similar.

-

Stroke: up to 300mm

-

Compatible motor: NEMA23 stepper or servo motor

TX SERIES LINEAR/ROTARY UNIT

TX SERIES LINEAR/ROTARY UNIT

The TX is based on the T series but adds a rotary motor to the shaft for a combined linear and rotary motion. This opens opportunities for pick-orient-place and capping applications.

The standard unit has a NEMA17 motor with gearbox with 2Nm max torque. We can also offer customised units.

ACCESSORIES

ACCESSORIES

-

Brackets for XYZ mounting

-

Motor mounts

-

Mounting plates

-

Rail mounts

-

Motor couplers

-

Gearboxes

-

Limit switches and sensors

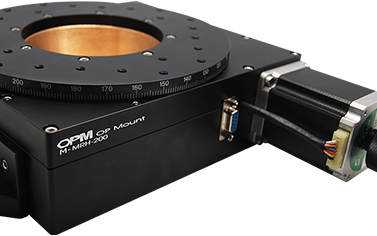

Motorised Rotary Stages

Excerpt for product to be confirmed

Ballscrew Linear Modules

Excerpt for product to be confirmed

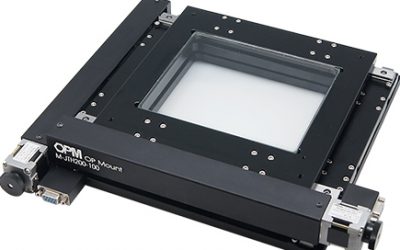

Motorised Microscope Stages

Our motorised microscope stages have been designed as drop-in replacements for manual…

Moving Iron Controllable Actuators

ORLIN Technologies Ltd, in partnership with innovative designer and manufacturer CEDR…