Programmable Controllers

We offer programmable controllers for all step motors with current per phase from 0.1A to 8.0A. SMSD stepper motor controllers provide advanced functionality with a choice of control modes and interfaces depending on application.

Control methods:

• Program control mode

• Real-time control by commands

• CANopen

• Analog speed control

• Analog position control

• Step/Dir pulse control

Interfaces:

• Ethernet TCP/IP

• CANopen

• RS-485

• RS-232

• USB

• Step/Dir pulses

• Analog 0 – 5 V

| STEPPER MOTOR CONTROLLER | MAX CURRENT PER PHASE (amp) | SUPPLY VOLTAGE | MICROSTEPPING | SIZE (mm) | ADDITIONAL |

|---|---|---|---|---|---|

| SMSD‑1.5 | 1.6 | 10 - 30 VDC | 1, 1/2, 1/4, 1/8, 1/16 | 23 x 83 x 116.5 | USB, RS232, RS485 analog speed control PULS/DIR + A-phase-B-phase |

| SMSD‑4.2LAN | 4.2 | 24 ‑ 48 VDC | 1, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128 | 120х110х35 | Ethernet, USB analog speed control, analog position control, PULSE/DIR |

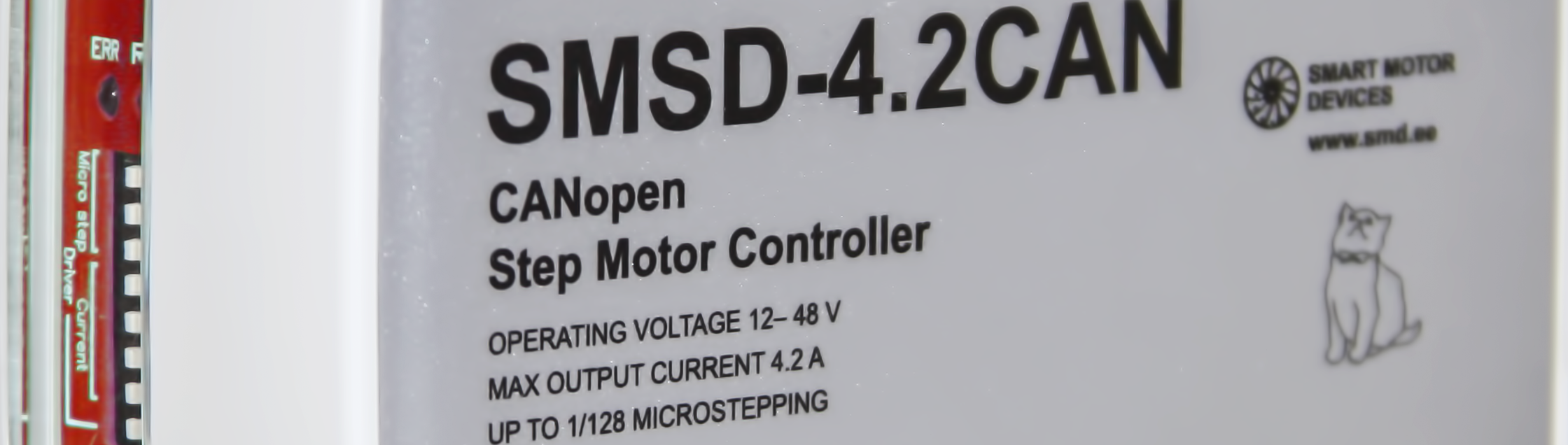

| SMSD‑4.2CAN | 4.2 | 12 ‑ 48 VDC | 1, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128 | 120x105x46 | USB, CAN - CANOpen: velocity control, position control, homing; PULSE/DIR |

| SMSD-8.0LAN | 8.0 | 24 ‑ 48 VDC | 1, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128 | 120х110х45 | Ethernet, USB analog speed control, analog position control, PULSE/DIR |

PROGRAM CONTROL MODE

This is the most common mode where a sequence of commands is stored in the controller memory and executed automatically. In this mode, the controller can run as a stand-alone unit without an external master device such as a PC or PLC. Motion sequences can be trigger by I/O signals with dedicated inputs for common functions, such as START, STOP, HOME etc.

This mode is convenient for automated machinery where repetitive movements are carried out with little interaction from the main controlling system.

Programming is carried out via a selection of interfaces, including RS232, RS485, CAN, Ethernet etc. Software for programming is provided free-of-charge.

REAL-TIME (DIRECT CONTROL) MODE

In this mode, commands are sent from a master device (e.g. PC or PLC) and are executed immediately by the controller. Such real-time control is convenient if the motion parameters are changed often or are not known in advance.

CANopen CONTROL MODE

All motion parameters are controlled via CAN interface, CANopen standard. It is the most suitable control mode for huge industrial systems, where different devices operates in conjunction.

ANALOGUE POSITION CONTROL MODE

The defined position is proportional to the analogue input voltage signal. The motion scaling is set via communication data protocol.

STEP / DIRECTION MODE

The last control mode is the same as in simple step motor drivers; position is set by pulse signal. There are two variations of this control mode: PULSE and DIR signals and A-phase and B-phase pulses with 90° (quadrature) difference.

If you would like to talk further about programmable controllers, please just get in touch!

CNC Machine Controllers

A Machine controller is a sophisticated device designed to control a complete process…

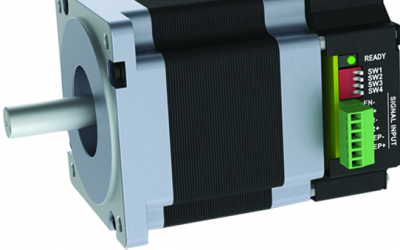

Integrated Stepper Motors

Integrated stepper motors have the driver mounted directly on the motor for ease of i…

Closed-Loop Servo Drives

A servo drive is an electronic unit that provides power and control to a servo motor…

Step-Direction Stepper Motor Drivers

Stepper Motors are widely used in CNC machines, robotics, process automation systems …