In automated food production lines, many moving parts are traditionally compressed air systems. In the past it was hailed as a cheap wonder fluid, but now there are many problems associated with the use of compressed air. In factory automation, compressed air is highcost and has a poor energy conversion (8HP energy converted to 1HP of air at the work point). Compressed air systems require a significant capital expense for the compressor and high maintenance costs and manhours to maintain it.

Compressed air systems are also a potential medium for spreading contaminants in food production lines. Food safety has a huge impact on profits, brand value and customer safety and companies producing and handling food items must take the elimination of contaminants seriously.

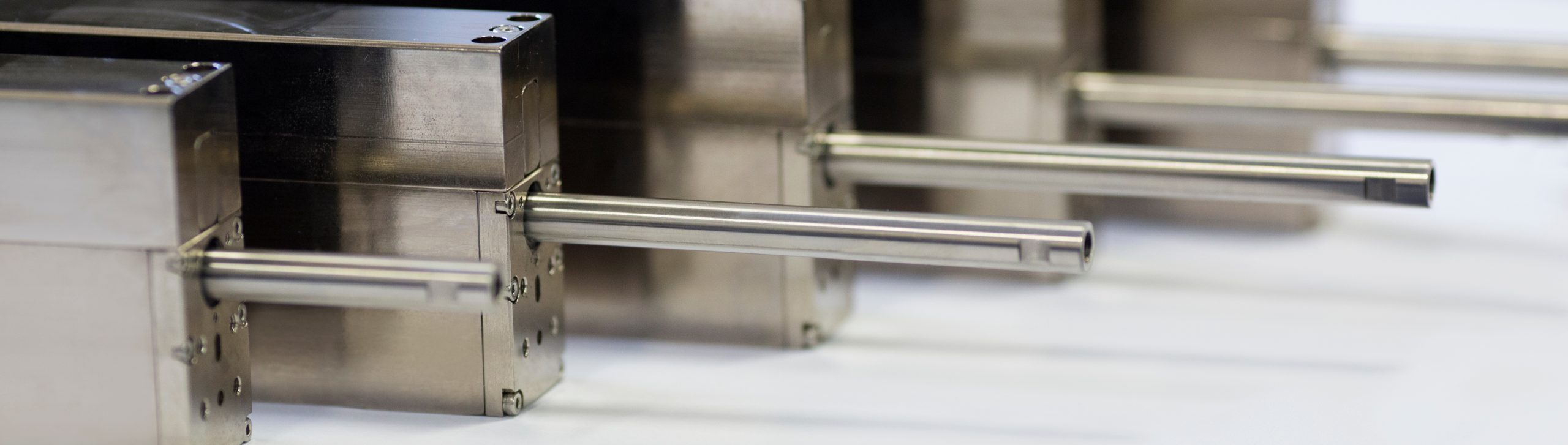

The electric actuators sold by ORLIN Technologies Ltd are used in safe food production and even in medical-grade clean room situations. Switching from compressed air to an electronic motion system, such as our SMAC Moving Coil Actuators, will provide better contamination prevention than the old systems.

Get in touch with us here at ORLIN to discuss your current system and we can have a chat about how it can be improved.