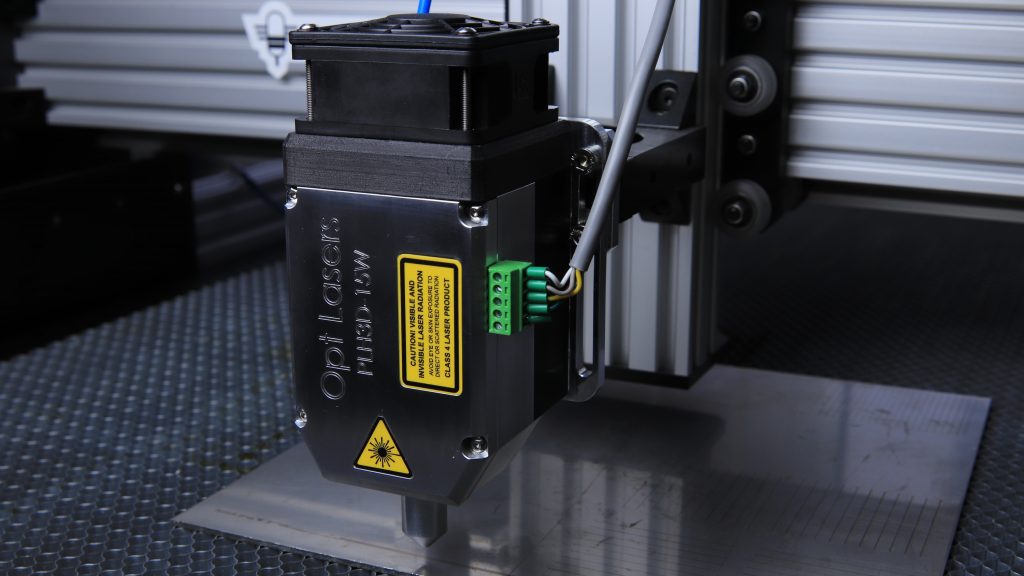

Some technologically advanced applications require an equally advanced degree of precision solutions, from laser marking to size changeover with absolute encoder solutions or touch probes to vision systems.

Some technologically advanced applications require an equally advanced degree of precision solutions, from laser marking to size changeover with absolute encoder solutions or touch probes to vision systems.

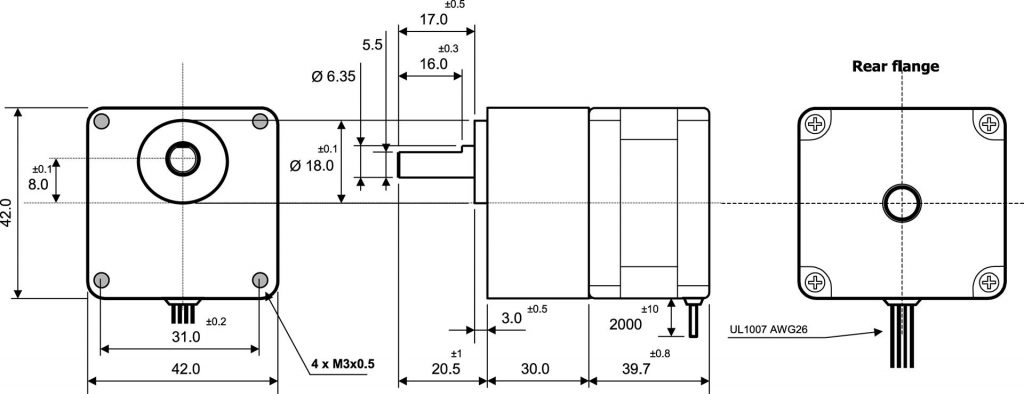

The use of unsuitable products, such as a motor that is too heavy, could generate the risk of causing less stability and thus lead to the motor itself losing its position.

In these cases, it is therefore important to keep the weight as low as possible in order to improve stability and movement dynamics – without compromising the accuracy of positioning.

How do I achieve this?

See below an example solution that was developed by Ever Elettronica from targeted testing.

The motor size is a significant weight minimiser; the integrated gearbox, in the absence of power supply, allows even higher torque to be delivered than larger motors (Nema 23 and Nema 24) and easily manages system inertia by avoiding any vibration.

The use of this type of solution shows an engine stability beyond expectations, even in stationary conditions.

Please just get in touch for a chat about a solution that could work for you.

High efficiency 2-step hybrid Nema 17 stepper motor with integrated gearbox

High efficiency 2-step hybrid Nema 17 stepper motor with integrated gearbox

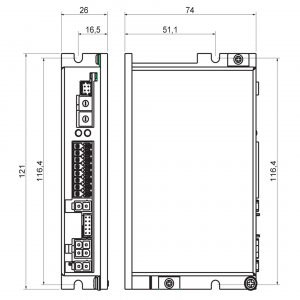

Fieldbus Programmable Vector Drive

Fieldbus Programmable Vector Drive