The Problem:

Shoe sorter stations rely on actuators to move a flipper that diverts boxes on a conveyor. Existing systems frequently experience broken flippers, inconsistent stroke lengths, and mounting complications. Repairs are costly and time-consuming, often requiring full station replacements or factory servicing.

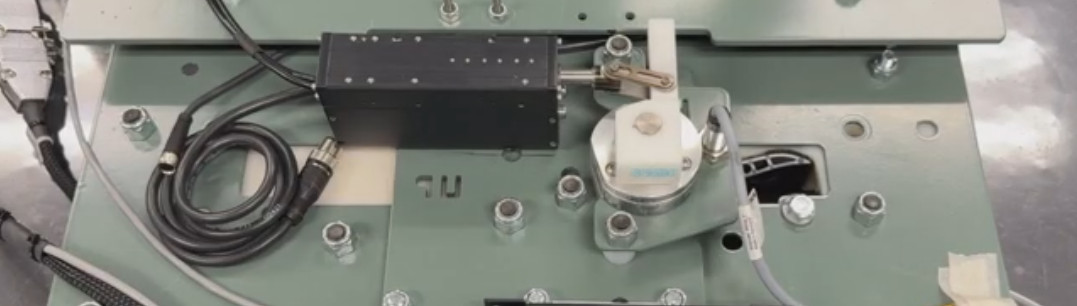

The SMAC Solution:

The LPL32 servo actuator offers precise motion control with soft end-of-stroke deceleration, dramatically reducing wear and tear. Its built-in oversized IKO linear guides deliver a cycle life of up to 100 million operations. The actuator self-calibrates by locating rear and front stops before cycling — enabling field replacement without manual adjustment.